How does AI optimize inventory management and demand forecasting?

Improve Efficiency with AI in Inventory Management and Demand Forecasting! 📦🔮

Introduction

In today's fast-paced business environment, efficient inventory management and accurate demand forecasting are critical for staying competitive. Artificial Intelligence (AI) plays a pivotal role in optimizing inventory levels and forecasting demand with precision. In this article, we'll explore how AI revolutionizes inventory management and demand forecasting processes, driving operational efficiency and business success.

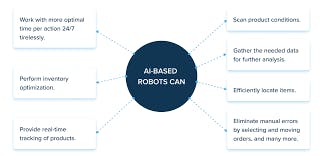

The Role of AI in Inventory Optimization

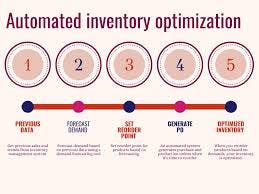

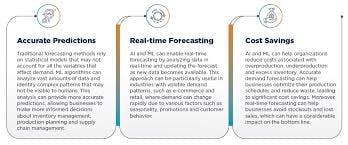

AI-powered inventory management systems leverage advanced algorithms and machine learning techniques to optimize inventory levels and reduce carrying costs. By analyzing historical data, current market trends, and other relevant factors, AI algorithms can predict demand patterns more accurately than traditional methods, leading to improved inventory turnover and reduced stockouts.

Demand Forecasting with AI

Demand forecasting is the process of predicting future demand for products or services. AI enhances demand forecasting accuracy by analyzing large volumes of data and identifying hidden patterns and correlations that human analysts may overlook. By considering factors such as seasonality, promotions, and external market conditions, AI algorithms can generate more precise demand forecasts, enabling businesses to align their inventory levels with expected demand.

Machine Learning Algorithms for Inventory Management

Various machine learning algorithms are used in inventory optimization, including neural networks, decision trees, and reinforcement learning. These algorithms analyze historical sales data, supplier lead times, and other relevant variables to determine optimal inventory levels and reorder points. For example, neural networks can identify complex relationships between different factors and predict future demand more accurately than traditional statistical methods.

Data Integration and Analysis

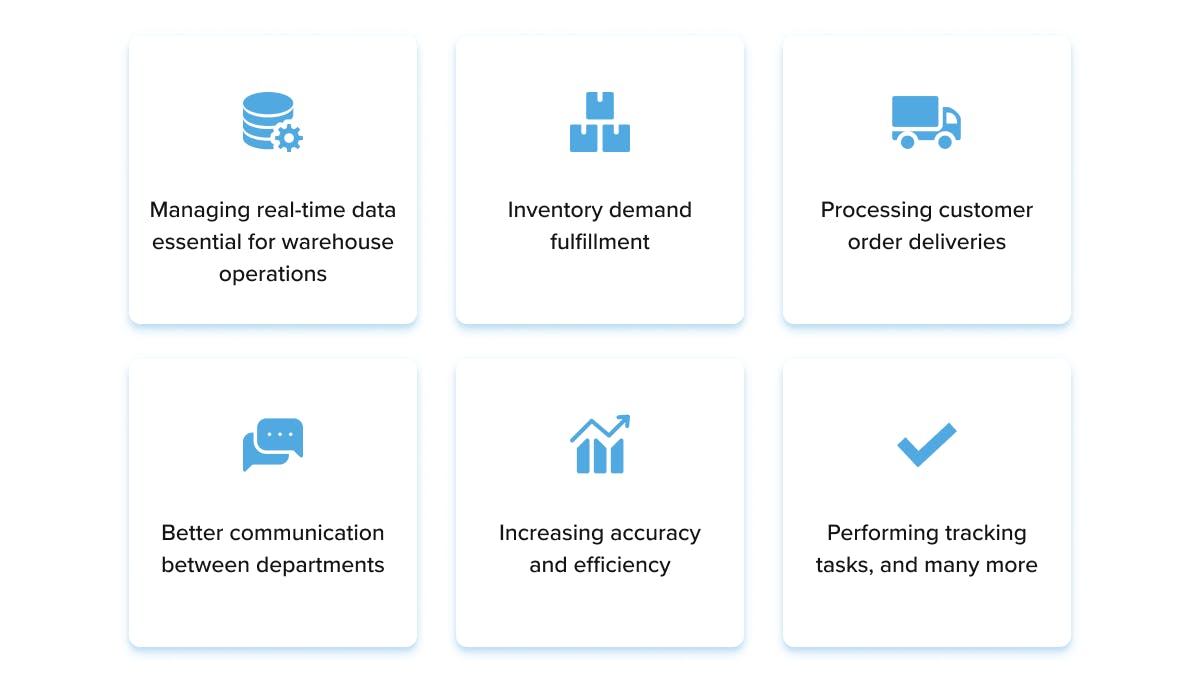

Effective inventory management requires integrating data from various sources, such as sales transactions, supplier records, and market trends. AI-powered systems consolidate and analyze this data in real-time, enabling businesses to identify trends and anomalies quickly. By processing large datasets efficiently, AI algorithms can provide actionable insights that help businesses make informed decisions about inventory levels and procurement strategies.

Real-Time Monitoring and Adaptation

One of the key advantages of AI in inventory management is its ability to monitor and adapt to changes in demand in real-time. By continuously analyzing incoming data and adjusting inventory levels accordingly, AI systems help businesses minimize stockouts and excess inventory. This agile approach allows companies to respond quickly to fluctuations in demand and maintain optimal inventory levels at all times.

Inventory Optimization Strategies

AI complements traditional inventory optimization strategies such as Just-in-Time (JIT) inventory management, Economic Order Quantity (EOQ) optimization, and Vendor-Managed Inventory (VMI) systems. By incorporating AI into these strategies, businesses can achieve greater precision and efficiency in managing their inventory, reducing costs and improving customer satisfaction.

Case Studies and Success Stories

Numerous companies across various industries have successfully implemented AI-driven inventory optimization solutions. For example, Amazon's use of AI-powered demand forecasting algorithms has enabled the company to minimize inventory holding costs while ensuring high product availability. Similarly, Walmart has leveraged AI to optimize inventory replenishment and reduce stockouts, resulting in significant cost savings and improved customer satisfaction.

Challenges and Limitations

Despite its benefits, AI-driven inventory management also presents challenges, such as data quality issues and organizational resistance to adopting new technologies. Businesses must address these challenges proactively to realize the full potential of AI in optimizing inventory levels and demand forecasting accuracy.

Future Trends and Innovations

Looking ahead, the future of inventory management will likely be shaped by advancements in AI and related technologies. Integration with Internet of Things (IoT) devices will enable real-time tracking of inventory movements, while predictive maintenance algorithms will help businesses identify and address supply chain disruptions before they occur.

Conclusion

In conclusion, AI has transformed inventory management and demand forecasting, empowering businesses to optimize inventory levels and enhance operational efficiency. By leveraging advanced algorithms and real-time data analysis, companies can minimize costs, reduce stockouts, and improve customer satisfaction.

As AI continues to evolve, businesses that embrace these technologies will gain a competitive edge in the dynamic world of supply chain management.

For more insights into AI|ML and Data Science Development, please write to us at: contact@fxis.ai| FxisAi

#AI #InventoryManagement #DemandForecasting 📦🔮